Digital Twin: Transforming Simulation with Cloud Computing and AI

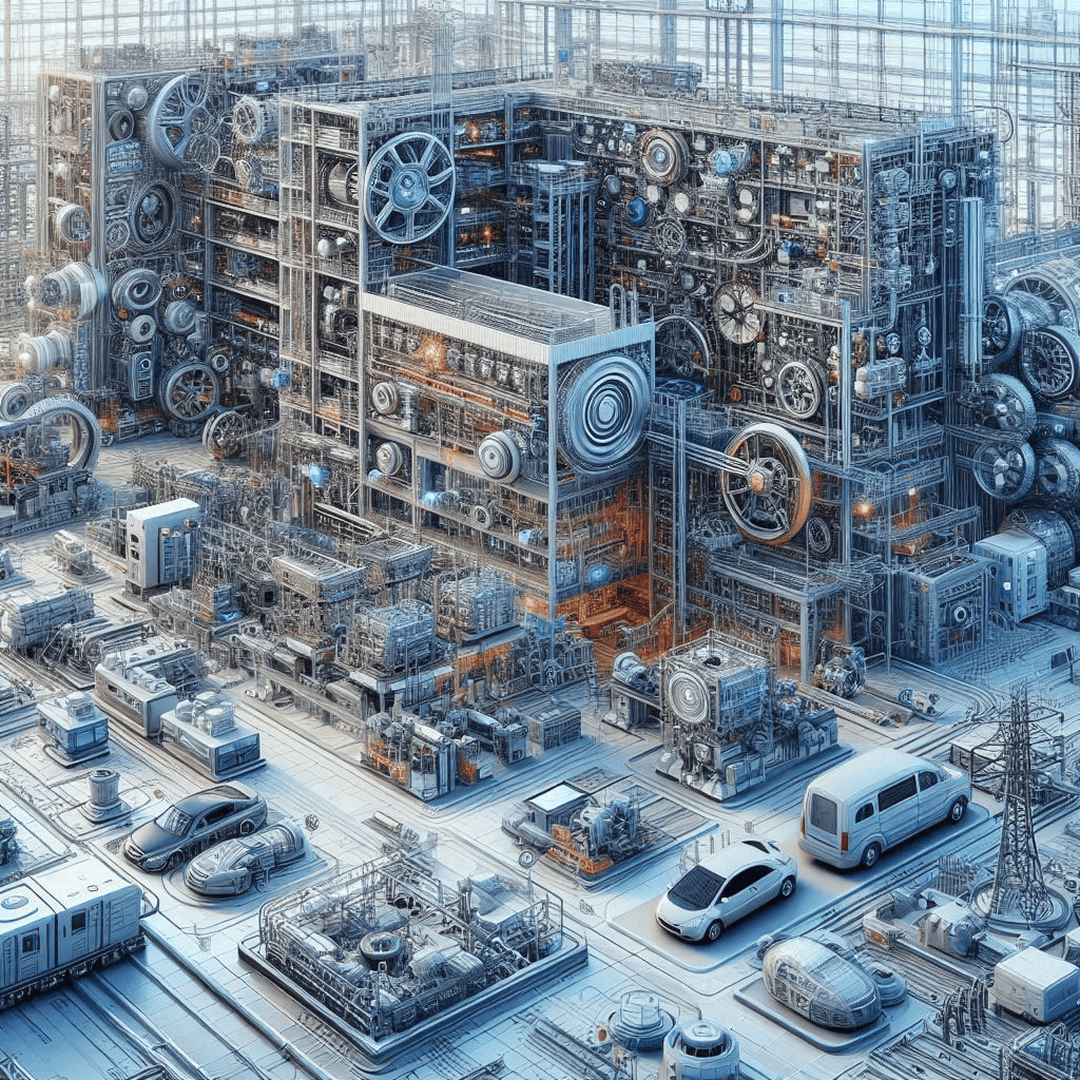

Model-Based Simulation Architecture (MBSA) is a sophisticated framework that leverages cloud computing and artificial intelligence to enhance simulation processes across various sectors, particularly in engineering and manufacturing. This architecture plays a crucial role in developing digital twins—virtual representations of physical systems—that allow for real-time monitoring, analysis, and optimization.

1. Conceptual Framework of Model-Based Simulation in Cloud Computing and Artificial Intelligence

At its core, Model-Based Simulation Architecture (MBSA) leverages digital twin technology to create virtual models of physical systems. These models simulate system behavior, enabling real-time monitoring, analysis, and optimization. The architecture is built on principles of system modeling and design, emphasizing the creation of abstract models that replicate complex systems.

The architecture comprises several layers:

1.1 Data Layer: This foundational layer manages data acquisition and storage, collecting real-time data from sensors and historical data from databases. It ensures that digital twin models receive accurate and relevant information.

1.2 Modeling Layer: This layer develops mathematical and computational models using techniques like finite element analysis (FEA) and computational fluid dynamics (CFD). These models form the backbone of digital twin simulations.

1.3 Simulation Layer: This layer executes simulations, analyzes results, and delivers insights into system behavior. It uses advanced computational techniques to enhance accuracy.

1.3 Visualization Layer: This layer presents simulation results through graphical representations, helping stakeholders understand complex data and make informed decisions.

2. Integration of Digital Twin Technology in Cloud Computing and Artificial Intelligence

Digital twin technology is a key application of MBSA, enabling the creation of virtual models that mirror physical systems. These models are continuously updated with real-time data, providing a dynamic and accurate representation of the physical entity.

2.1 Digital Twin Architecture

The architecture of a digital twin typically includes three main components:

-Physical Entity: The actual system or object being modeled.

-Digital Model: The virtual representation of the physical entity, updated in real-time.

-Data Connection: Facilitates real-time data flow between the physical entity and the digital model using sensors and communication technologies.

This architecture enables continuous monitoring, predictive maintenance, and performance optimization, making digital twins indispensable in modern industries.

3. Methodologies in Model-Based Simulation for Cloud Computing and Artificial Intelligence

MBSA employs various methodologies to enhance simulation accuracy and efficiency:

-System Dynamics: Models complex systems over time using feedback loops and time delays.

-Agent-Based Modeling: Simulates interactions of autonomous agents within a system.

-Discrete Event Simulation: Models systems as a sequence of events, ideal for manufacturing and logistics.

-Finite Element Analysis (FEA): Solves complex structural and thermal problems by dividing systems into smaller elements.

4. Applications of Model-Based Simulation Architecture in Cloud Computing and Artificial Intelligence

MBSA, powered by digital twin technology, has diverse applications:

-Manufacturing: Optimizes production processes, reduces waste, and improves product quality.

-Healthcare: Simulates patient flow and optimizes resource allocation.

-Transportation: Models traffic flow and improves logistics.

-Energy Management: Simulates energy consumption patterns and optimizes grid management.

5. Challenges and Future Directions in Cloud Computing and Artificial Intelligence

Despite its advantages, MBSA faces challenges:

-Data Quality and Availability: Accurate simulations depend on high-quality data.

-Complexity of Models: Balancing model complexity with computational efficiency is crucial.

-Integration with Existing Systems: Requires significant changes to workflows and data management.

Future directions include:

-Advancements in Machine Learning: Enhances model accuracy and predictive capabilities.

-Enhanced Visualization Techniques: Uses VR and AR for better data interpretation.

-Real-Time Simulation: Enables live data-based decision-making.

Conclusion

In conclusion, Digital Twin for Resource Management in Manufacturing represents a transformative approach to optimizing operations and enhancing decision-making. By leveraging Model-Based Simulation Architecture (MBSA) integrated with cloud computing and artificial intelligence, organizations can achieve real-time monitoring, predictive maintenance, and efficient resource allocation. As industries continue to embrace digital transformation, the adoption of digital twin technology will play a pivotal role in driving innovation, reducing costs, and improving overall system performance. The future of manufacturing and beyond lies in the seamless integration of digital twins, enabling smarter, more sustainable, and highly efficient operations.

Do you like to read more educational content? Read our blogs at Cloudastra Technologies or contact us for business enquiry at Cloudastra Contact Us.