Heterogeneous Networks in Smart Manufacturing Factory

1. Introduction

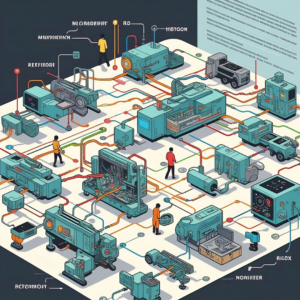

The evolution of smart manufacturing has been significantly influenced by the integration of advanced information and communication technologies (ICT) with traditional manufacturing processes. This convergence has led to the emergence of heterogeneous networks, which combine both wired and wireless communication technologies to support the diverse needs of smart factories. Effective network management plays a crucial role in ensuring the seamless interconnection of various intelligent devices, including production equipment, sensors, and logistics systems, which are essential for achieving high levels of automation and efficiency.

In a smart manufacturing environment, the diversity of devices and their communication protocols presents a significant challenge. Devices from different manufacturers often employ varying standards and protocols, leading to interoperability issues. Moreover, the coexistence of wired and wireless networks introduces complexities in managing data transmission, ensuring quality of service (QoS), and maintaining network reliability. The need for low latency, high reliability, and robust security measures is paramount, as these factors directly impact the performance and efficiency of manufacturing operations.

2. Classification and Key Technologies of Heterogeneous Networks

Heterogeneous networks in smart manufacturing can be classified into three main categories: industrial wired networks, industrial wireless networks (IWNs), and power line carrier (PLC) communication. Effective network management is essential to ensure seamless integration, reliability, and security across these diverse communication systems.

2.1. Industrial Wired Networks

These networks utilize various physical media, including twisted pairs, coaxial cables, and optical fibers. They are known for their high reliability and fast data transmission capabilities. Common protocols include Modbus, PROFInet, and EtherCAT, which are widely used in factory automation. However, the rigidity of wired networks can limit flexibility and scalability in dynamic manufacturing environments.

2.2. Industrial Wireless Networks (IWNs)

IWNs offer the advantage of mobility and ease of deployment. They support various communication protocols, including Wi-Fi, Zigbee, and Bluetooth, which enable real-time data exchange between devices. Despite their benefits, IWNs face challenges such as interference, signal attenuation, and security vulnerabilities, which can affect their performance in industrial settings.

2.3. Power Line Carrier (PLC) Communication

PLC technology leverages existing electrical wiring to transmit data, providing a cost-effective solution for connecting devices in environments where deploying new cables is impractical. However, PLC communication can be hindered by noise and signal degradation, necessitating advanced modulation techniques to ensure reliable data transmission.

3. SDN- and EC-Based Heterogeneous Networks Framework for Smart Factories

To address the challenges posed by heterogeneous networks, a Software-Defined Networking (SDN) and Edge Computing (EC)-based framework has been proposed. This architecture separates the control plane from the data plane, allowing for more flexible and efficient network management of resources.

3.1. East-West Flow Plane

This plane facilitates communication between devices within the factory, enabling real-time data exchange and collaborative operations. The east-west flow is characterized by high data volume and diverse types of information generated by various devices, necessitating efficient data processing and transmission strategies.

3.2. North-South Flow Plane

This plane connects the factory network to external cloud services, allowing for data aggregation, analysis, and storage. The north-south flow is crucial for leveraging cloud computing capabilities to enhance decision-making and optimize manufacturing processes.

3.3. Computing Plane

The computing plane encompasses edge computing resources that process data closer to the source, reducing latency and bandwidth requirements. By deploying edge computing nodes, manufacturers can achieve real-time data processing and analytics, enabling faster responses to changing operational conditions.

4. AI-Enabled QoS Optimization of Heterogeneous Networks

Quality of Service (QoS) optimization is critical for ensuring that heterogeneous networks meet the diverse requirements of smart manufacturing applications. AI-driven approaches are increasingly being utilized to enhance QoS by optimizing network performance in terms of latency, reliability, and security. Effective network management plays a crucial role in maintaining these performance standards, ensuring seamless connectivity and efficient resource allocation.

4.1. Cloud-Assisted Ant Colony-Based Low Latency of Mobile Handover

This strategy employs ant colony optimization algorithms to manage mobile node handovers, minimizing latency during transitions between access points. By intelligently predicting the optimal handover paths, manufacturers can ensure continuous connectivity for mobile devices operating within the factory.

4.2. Data Transmission Strategies with Different Delay Constraints

Different manufacturing applications have varying latency requirements. For instance, real-time control systems may require sub-20 ms latency, while less critical applications can tolerate higher delays. Implementing adaptive data transmission strategies allows for prioritization of critical data flows, ensuring that time-sensitive information is transmitted promptly.

4.3. Load-Balanced Packet Broadcast Scheme Based on Neighbor Information

This scheme utilizes information about neighboring nodes to optimize packet transmission across the network. By balancing the load among multiple paths, manufacturers can enhance network throughput and reduce congestion, leading to improved overall performance.

4.4. Network Load Balancing and Routing Optimization Based on Deep Reinforcement Learning

Deep reinforcement learning algorithms can dynamically adjust routing paths based on real-time network conditions. This approach enables the network to adapt to changing demands, ensuring optimal resource utilization and minimizing latency.

4.5. Blockchain for Network Security and Privacy Protection

The integration of blockchain technology enhances the security and privacy of data transmitted across heterogeneous networks. By providing a decentralized and tamper-proof ledger, blockchain can help secure sensitive manufacturing data and ensure compliance with regulatory requirements.

5. Validation of QoS Optimization Methods of Heterogeneous Networks

To validate the effectiveness of the proposed QoS optimization methods, various experimental setups have been designed. These experiments assess the performance of different algorithms under varying network conditions, including bandwidth limitations and latency constraints, providing valuable insights for efficient network management.

5.1. Validation of EC Proactive Caching for Low Latency

Edge computing nodes can cache frequently accessed data, reducing the need for repeated data retrieval from the cloud. This proactive caching strategy has been shown to significantly lower latency, particularly for applications requiring real-time data access.

5.2. Validation of Mobile Handover Latency Optimization

Experiments demonstrate that the cloud-assisted mobile handover strategy effectively reduces latency during transitions between access points. By minimizing the time required for handovers, manufacturers can maintain uninterrupted connectivity for mobile devices.

5.3. Validation of Load Balancing and Routing Optimization

The performance of load balancing and routing optimization algorithms has been evaluated under different network topologies. Results indicate that these algorithms improve network throughput and reduce congestion, leading to enhanced overall performance.

6. Conclusion

The integration of heterogeneous networks in Smart Manufacturing factories is essential for achieving the goals of Industry 4.0. By leveraging a combination of wired and wireless communication technologies, manufacturers can create flexible and scalable network infrastructures that support the diverse needs of modern production environments. Effective network management plays a crucial role in maintaining seamless connectivity, optimizing resource allocation, and ensuring security across these complex systems. The adoption of SDN and edge computing frameworks, along with AI-driven QoS optimization strategies, enables manufacturers to enhance network performance, reduce latency, and improve reliability. As the manufacturing landscape continues to evolve, the importance of robust and efficient heterogeneous networks will only increase. By addressing the challenges associated with interoperability, security, and performance, manufacturers can unlock the full potential of Smart Manufacturing, driving innovation and competitiveness in the global market.

Do you like to read more educational content? Read our blogs at Cloudastra Technologies or contact us for business enquiry at Cloudastra Contact Us.