Water Treatment Engineering Design Innovation, the development of treatment process innovations and technological advancements for water treatment design, is perhaps one of the fastest advancing sectors within modern environmental engineering. However, despite the large number of scientific breakthroughs, modeling tools, and other tools being developed by academia, there continues to be a significant gap between research results and their actual use in treatment plant operation. While there are many sophisticated algorithms for optimizing treatment systems, and many models for optimizing the operation of reservoirs, they are rarely implemented by treatment plants. Several studies have documented that treatment plant managers will generally prioritize short-term compliance with existing regulations and the financial feasibility of treatment options. They do this prior to investing in any experimental or novel treatment processes. This results in a slow rate of technology transfer.

This paper provides an overview of the reasons that contribute to the knowledge gap between water treatment engineering research and practice. It also reviews some potential solutions to this problem and includes examples of successful applications of research-based treatment technology. By recognizing these obstacles and opportunities, researchers, engineers, and policy makers should be able to more closely coordinate their efforts. This will help them provide more effective and sustainable treatment technologies.

Causes of the Research-Practice Gap

1. Inadequate Collaboration

Collaboration among researchers in academia and practitioners (operators) in the water industry is a long-standing problem area in water treatment engineering. Practically all researchers develop complex mathematical or computational models for water treatment design processes based upon theoretical considerations of how a particular unit operation functions. However, few of the researchers consider the operational constraints faced by treatment plant operators including the budget available for operating and maintaining the treatment plant; the level of staffing and training available to operate and maintain the equipment; and the legal/ regulatory framework that governs the treatment of wastewater discharges from the facility. As a result, many theoretically sound, algorithmic approaches for optimizing treatment processes are never tested at scale in treatment plants.

2. Limited Awareness and Technical Training

Treatment plant operators and engineers may be unfamiliar with the latest and best available treatment optimization techniques and/or lack the necessary technical education/training to use them properly. This creates a skills gap in which research results are not effectively communicated or transferred into formats useful to practicing treatment plant engineers. For example, a 2023 Water Research Foundation survey found that less than 20% of water utilities currently engage in partnerships with universities to evaluate new treatment technologies or processes.

3. Financial and Regulatory Barriers

In addition to the availability of capital funds for implementing new technologies, treatment plant managers must also comply with federal, state and local regulations governing the treatment of wastewater discharges. Treatment plant managers are typically focused on meeting current regulatory requirements and minimizing short term costs of operating and maintaining the treatment plant. Consequently, they are often unwilling to invest time and money in experimental treatment processes that do not meet those short-term goals. Regulatory agencies may also be reluctant to certify or approve new treatment technologies until they have been extensively tested under field conditions.

4. Data Collection and Access Barriers

Finally, reliable, consistent data collection is essential to calibrate and validate predictive models of treatment processes. However, much of the data collected in treatment plants today is either scattered across various data management systems or is stored in formats incompatible with analysis software. Moreover, the lack of standardization in data collection practices makes it difficult to apply more advanced predictive models to optimize treatment process design.

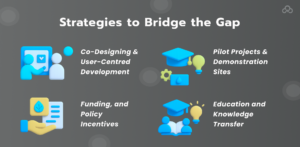

Strategies to Bridge the Gap

To address these issues, numerous research-based integrated strategies are being constructed to strengthen the connection of research with operational practice.

1. Co-Designing and User-Centred Development

The involvement of a research team including utility operators, technicians and policy makers from the earliest stages of modeling should also be encouraged. By working on a user-centred design framework new tools should be more intuitive and flexible to real operation. The use of collaborative workshops and co-creation of frameworks ensures that theness and practical use is obtained.

2. Pilot Projects and Demonstration Sites

Pilot tests provide the proof of concept and data gathered from performance tests under real operating conditions. Demonstration sites such as those generated under the UK Water Industry Research Programme have been invaluable in determining the value of new water treatment wastewater technologies prior to full scale utilization. Pilot projects also provide the training grounds for operators so that they can become user-friendly with new systems.

3. Funding, and Policy Incentives

Government grants and international funding mechanisms may result in innovation being possible thus releasing the financial burden placed on utilities. For example, activities encouraged through European Partnerships through the European Union under its Horizon 2020 scheme have facilitated many collaborative projects on sustainable treatment system design which embraces resource recovery facilities and energy neutral wastewater plants.

4. Education and Knowledge Transfer

Examples of capacity building mechanisms such as cross-sector training, certification programmes and university and industry partnerships are essential to long term sustainability.

Workshops that concentrate on the practical application of knowledge rather than just theory help ensure that the academic work leads directly to operational improvements. Ongoing professional development also assists adaptation among engineers and plant operators.

Research to Practice: Water Treatment Engineering

The term Research to Practice Water Treatment design gives meaning to the transformation of theoretical results into real-world solutions. The past decade has seen a worldwide momentum in research initiatives for the introduction of membrane filtration, biological nutrient removal, and smart monitoring systems into conventional wastewater treatment works.

Recent Developments in Water Treatment Engineering

– Membrane Bioreactor (MBR): The combination of biological treatment and membrane filtration for improved effluent quality and compact systems.

– Advanced Oxidation Processes (AOP’s): The application of hydroxyl radicals for breakdown of complex contaminants, for example, pharmaceuticals and microplastics.

– Decentralised Treatment Units: Small modular units for treatment of waters suited for example, to rural or off grid communities.

– Smart monitoring and automation: The integration of sensors and IoT technology for in-time monitoring of water quality and predictive maintenance.

Apart from the technical side bridging research and practice requires strong working collaboration between universities and governmental agencies and utilities. There are now joint research centres which are developing open-access simulation tools for engineers to test system configurations in various conditions before physical implementation. Cost is reduced and time for implementation is shortened through this co-development method, while it enables system designs to be locally adaptable. The introduction of new frameworks with a focus on scalability of size and circularity means that water treatment design systems can be designed in a way that they are not only technically correct, but also socio-economically viable.

The global report compiled by BlueTech Research 2024 estimates that smart water technologies provide 25-30% more operational effectiveness in large scale treatment works. This trend identifies a turn to data-based engineering designs promoting sustainability and durability of systems. Further, AI controlled systems are now used for the dynamic adjustment of aeration rates, improvement of chemicals dosing, and prediction of failures in the systems that greatly reduce energy consumption and unplanned downtime. These are examples of a continuously evolving discipline of water treatment design. It is an interdisciplinary area in which computer science, engineering and environmental management converge.

Examples of Research-Practice Transformation

1. AI drive optimisation for reservoir scenarios.

Pilot studies carried out in Southeast Asia demonstrate how machine learning algorithms can assess and optimise water storage and release sentiments of water to maximise water quality and reduce wastage.

2. Digital Twin Systems. Wastewater Treatment.

Digital twins of treatment works, these virtual replicants permit the operators to experiment in real-time with scenarios of varying operations. Cities like Singapore and Copenhagen have adopted these models for improved efficiency in operations.

3. Open-Source Collaborations.

The US Environmental Protection Agency’s Water Research Programme works collaboratively with universities to develop open-source simulation systems usable by utilities in that they have no high costs of licensing.

These are examples of collaborations wherein positive work is greatly accelerated and leads to the more rapid acceptance of innovative solutions for more efficient and sustainable water systems.

Conclusion

In order to bridge the divide between research and practice in water treatment design will require more than innovation; it will require collaboration, accessibility, and supportive policies. By fostering a dialogue between researchers and practitioners, jointly developing tools that are practical and simple to use, and enacting powerful funding mechanisms we can transform theoretical breakthroughs into practical, scalable and sustainable solutions.

In order to maintain the pace of rising global demand for fresh water, the future of water treatment design and water treatment engineering will hinge on the convergence of data analytics, automation, and community based design engineering. Engineers must emphasize flexibility and resilience such that each individual breakthrough can be linked effectively to both technical performance and environmental stewardship. Therefore, bridging this gap does not involve merely the use of technology, but entails the conversion of knowledge into public benefit and the establishment of systems designed to protect water cequity for generations yet unborn.

Technical FAQs

1. What is the importance of integrating AI in water treatment design?

AI enables process optimization and predictive control in water treatment through analysis of real time data, resulting in minimized chemical and energy consumption and consistent output quality, which equate to both improved operational efficiency.

2. How does digital twin technology facilitate improvements in treatment system design?

By emulating the treatment plant processes, such that designers can examine the results achieved by conceptual design changes before application thereof, thus reducing risk, expense and downtime and maximizing data based decision-making capability.

3. What are the primary challenges in application of academic models to practice?

The basic impediments to implementation are inconsistent data bases, inadequate operator training and high initial costs. Since progress toward overcoming these obstacles will require joint design efforts, enhanced data assimilation, and supportive funding.

4. How can utilities stimulate the existent swifter application of innovative technologies in waste-water treatment?

Utilities can promote schemes of co-operative establishment of research participation in pilot projects and take advantage of incentive achievable thru policy formulation.

Diligent staff education and co-operation with vendors of newer items on the market is required.

Do you like to read more educational content? Read our blogs at Cloudastra Technologies or contact us for business enquiry at Cloudastra Contact Us.